Back Filling Compound

MOQ : 1 Piece

Back Filling Compound Specification

- Shape

- Granular

- Molecular Weight

- 252.33 g/mol

- Molecular Formula

- C8H18NaO2PS2

- Melting Point

- >100C

- Grade

- Industrial

- Application

- Earthing systems, Electrical grounding

- Appearance

- Powder

- Shelf Life

- 12 months

- Smell

- Odorless

- Physical Form

- Solid

- Ph Level

- 7-8

- Poisonous

- No

- Usage

- Enhances conductivity, Reduces soil resistivity

- Density

- 1.30 Gram per cubic centimeter(g/cm3)

- Taste

- Odorless

- Storage

- Cool, dry place away from moisture

- Other Names

- Earthing Compound, Earthing Backfill

- HS Code

- 382490

- Classification

- General Reagents

- Chemical Name

- Sodium Diisobutyl Dithiophosphate

- Type

- Back Filling Compound

- Purity(%)

- 99%

- Color

- Grayish

- Eco-Friendly

- Environmentally safe

- Heavy Metal Content

- Negligible

- Particle Size

- <75 microns

- Conductivity

- Highly conductive

- Compressive Strength

- High

- Solubility

- Soluble in water

- Packaging Size

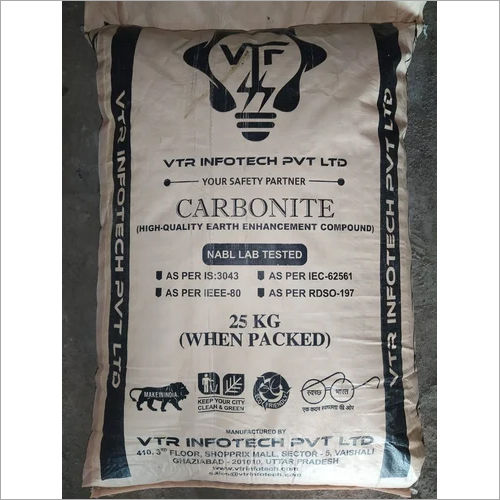

- 25 kg bags

- Moisture Absorption

- Excellent

- Non-Corrosive

- Yes

Back Filling Compound Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 2 Days

- Main Domestic Market

- All India

About Back Filling Compound

Back Filling Compound, also known as backfill material or simply backfill, refers to a material that is used to fill the space between a buried pipeline or underground structure and the surrounding soil. The purpose of backfilling is to provide support and stability to the structure, protect it from external forces, and prevent water from infiltrating and damaging the structure. Back Filling Compound is typically made of natural or synthetic materials such as sand, crushed rock, or concrete.

Superior Conductance for Reliable Grounding

Formulated for high conductivity, our back filling compound significantly lowers soil resistivity, ensuring stable and efficient electrical grounding. Its granular, powdery form enables thorough soil integration for optimal performance in earthing systems.

Eco-Friendly and Safe Choice

This compound is environmentally responsible, non-corrosive, and free from harmful heavy metals. Safe to handle and odorless, it delivers effective results without compromising sustainability or user safety.

Versatile Applications Across Installations

Ideal for electrical earthing, utility substations, and other industrial grounding systems, the compounds high compressive strength and excellent moisture retention make it a reliable choice in varied soil conditions and climates.

FAQs of Back Filling Compound:

Q: How is the back filling compound applied in earthing systems?

A: The compound is mixed or poured around ground electrodes or earthing rods to enhance the contact surface area and lower soil resistivity. It should be used according to standard installation procedures and kept moist after application for best results.Q: What benefits does this back filling compound offer compared to traditional materials?

A: It provides high electrical conductivity, maintains effectiveness even with moisture variation, is non-corrosive to metals, eco-friendly, and offers excellent compressive strength, thus ensuring longer service life for earthing systems.Q: When should this back filling compound be used during the installation process?

A: Apply the compound during the installation of earthing electrodes or systems, after digging and before refilling the earth pit. Adding it at this stage maximizes conductivity and soil contact.Q: Where can this back filling compound be most effectively utilized?

A: It is especially effective in industrial sites, electrical substations, and areas where consistent, low-resistance grounding is required. Its formulation makes it suitable for varied soil types and moisture conditions.Q: What precautions should be taken while storing the compound?

A: Store the compound in a cool, dry area away from moisture and direct sunlight. Ensure bags remain sealed until use to preserve the products integrity and effectiveness throughout its 12-month shelf life.Q: What is the typical process for using the compound in earthing applications?

A: Excavate the desired area, place the earthing electrode, then surround it with the back filling compound before refilling with soil. Moisture can be added to expedite settling and activation of the compound.Q: What is the environmental impact of this back filling compound?

A: The compound is environmentally safe, non-corrosive, and contains negligible heavy metals, meaning it poses no risk to soil or groundwater and aligns with sustainable construction practices.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Earthing Compound Category

Conductive Concrete Compound

Minimum Order Quantity : 1 Piece

Purity(%) : 99%

Classification : General Reagents

Chemical Name : Sodium Diisobutyl Dithiophosphate

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese